Introduction |

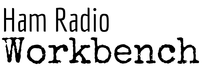

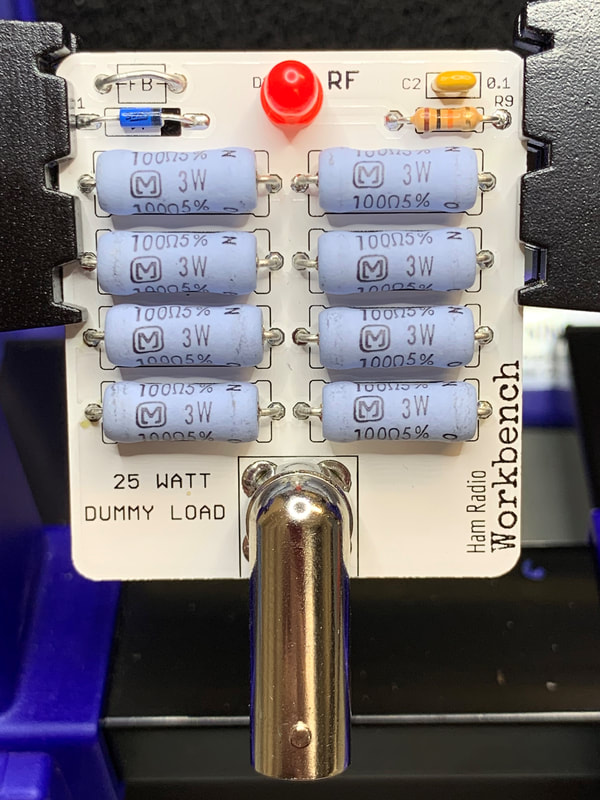

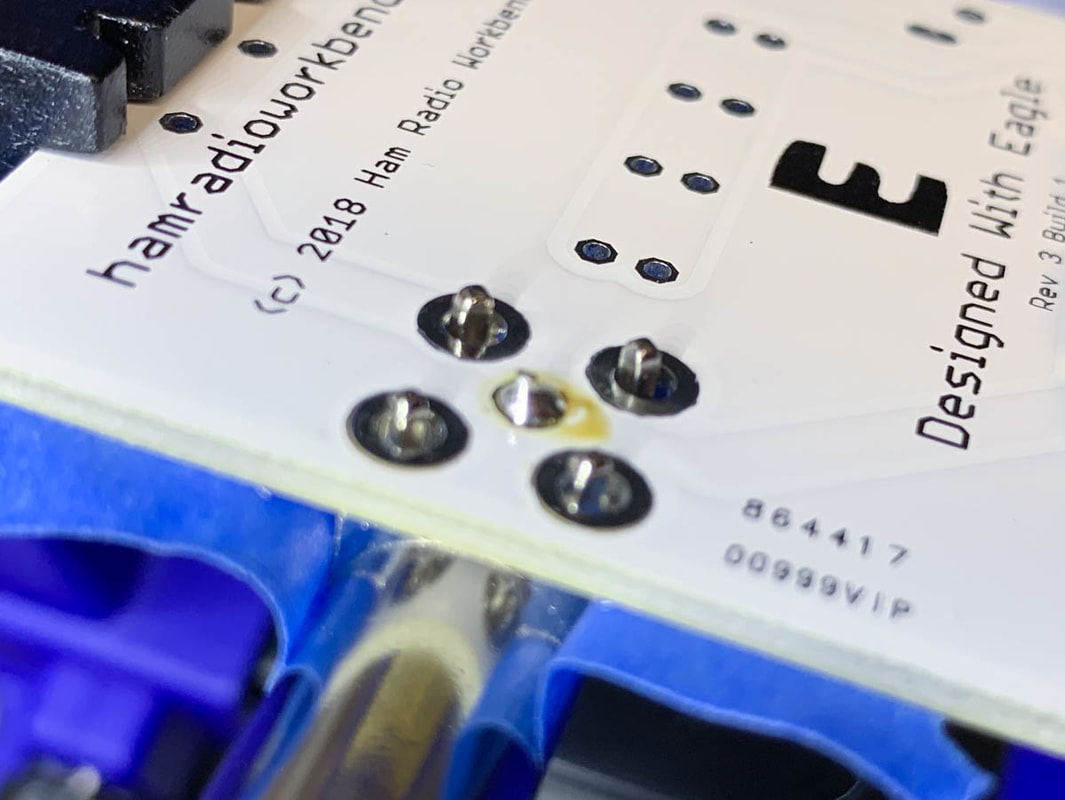

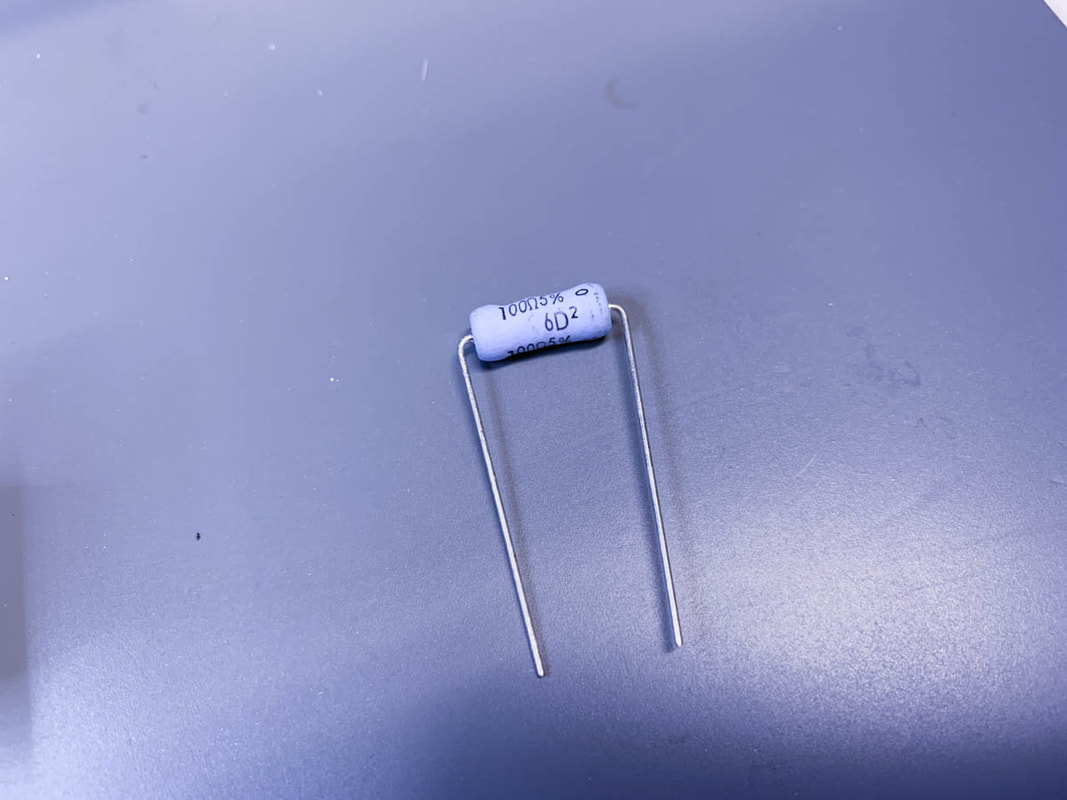

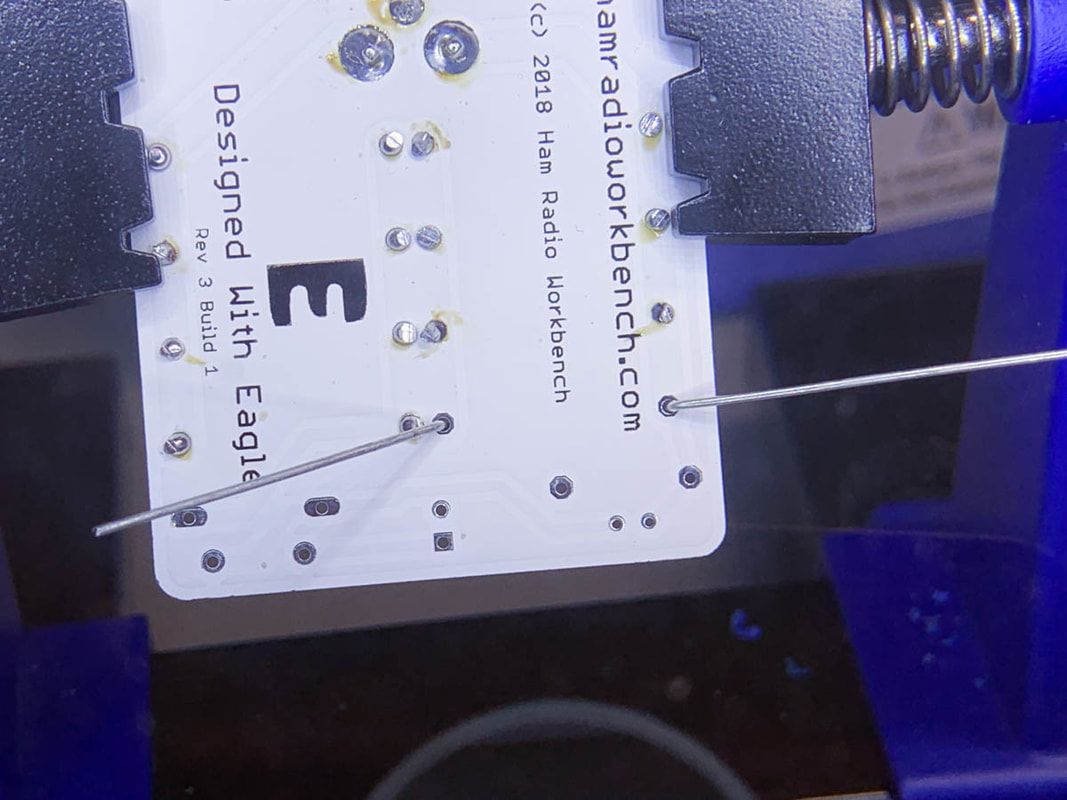

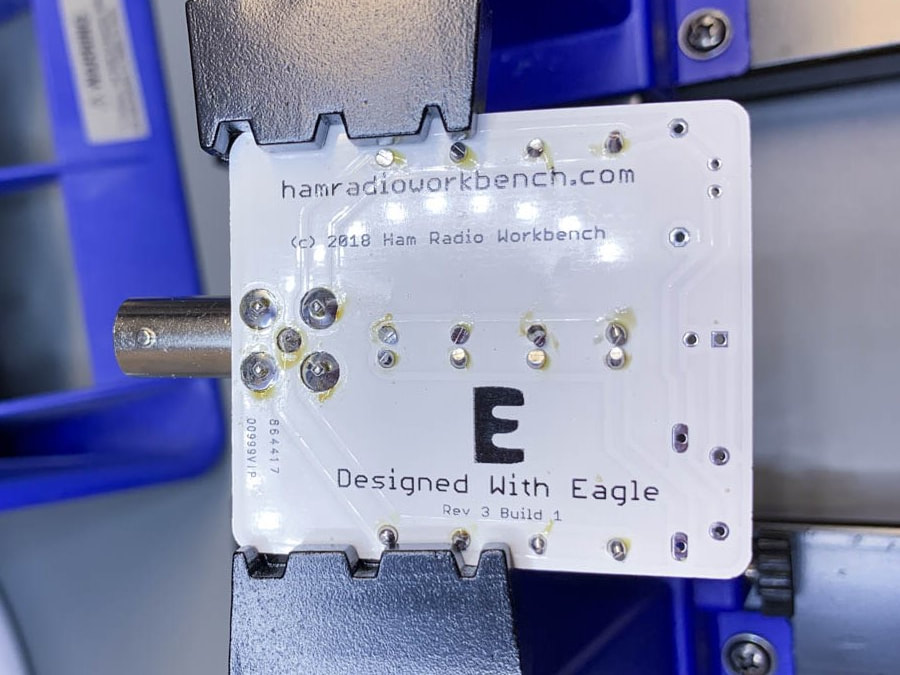

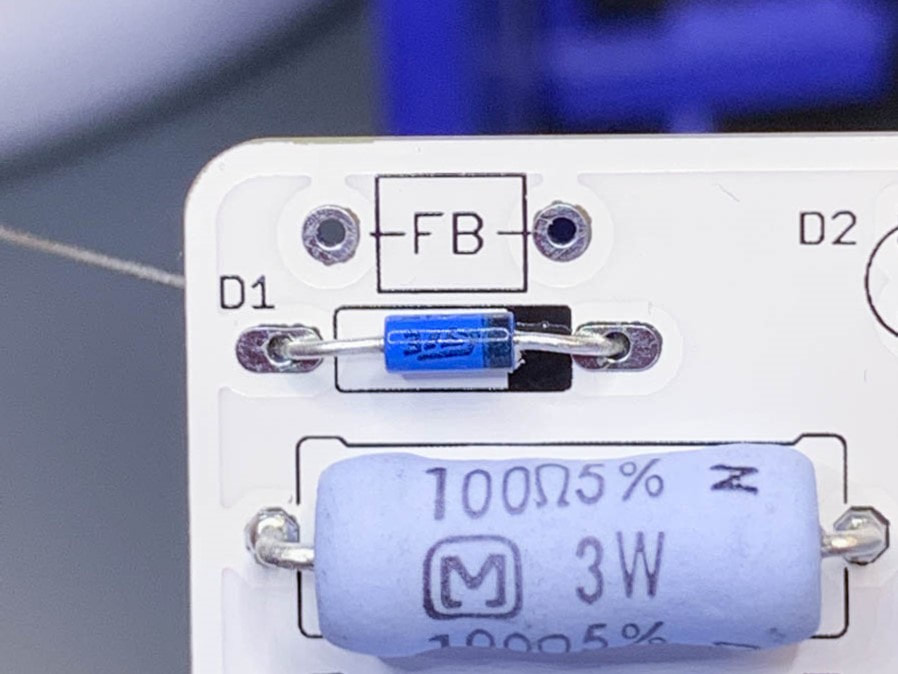

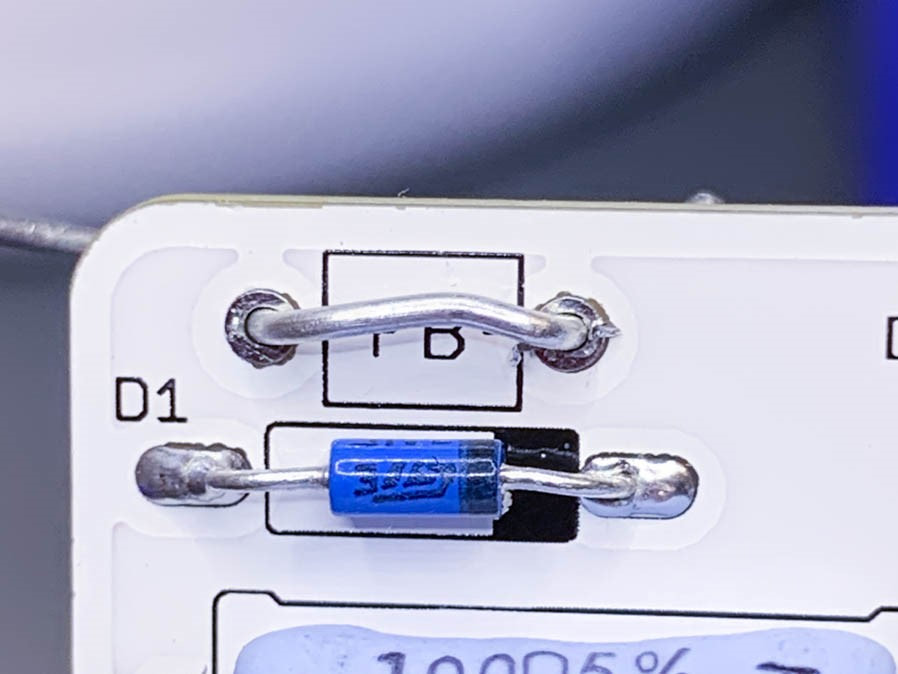

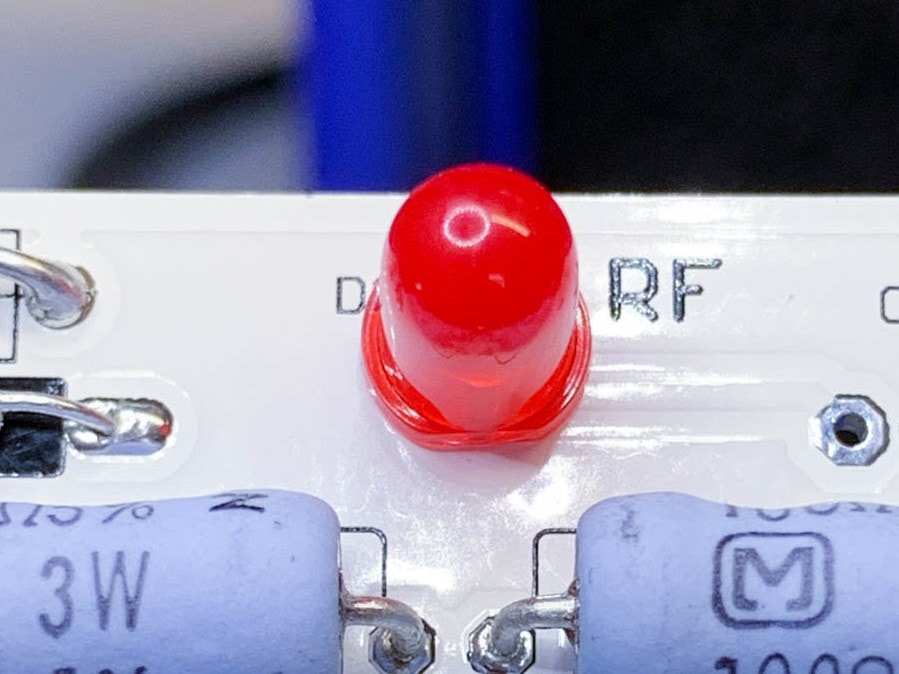

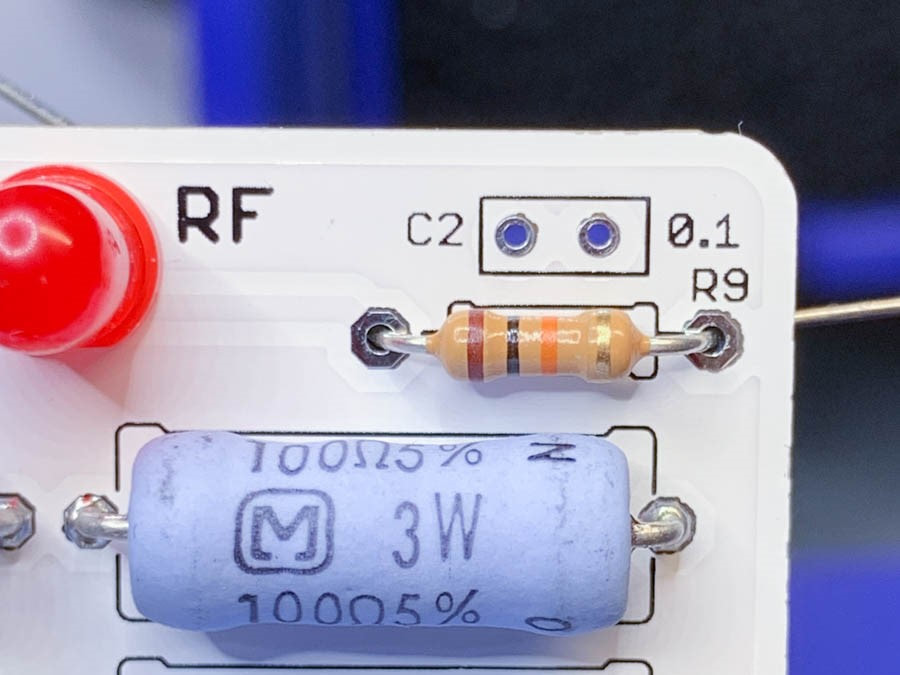

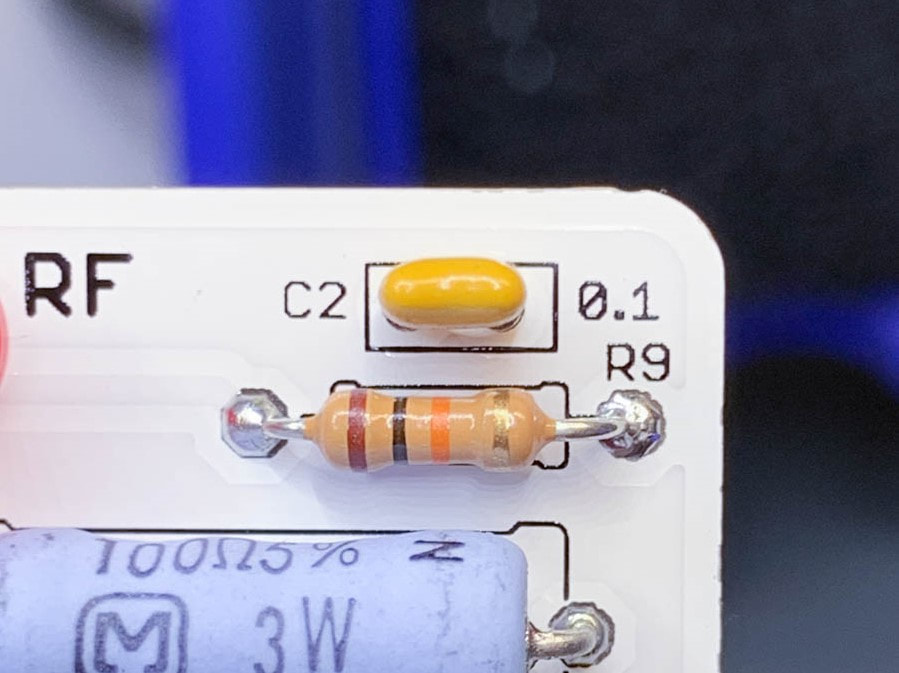

A perfect introduction to through-hole soldering, the Ham Radio Workbench QRP Dummy Load project rated for short bursts of up to 25 Watts with an LED that indicates the presence of RF.

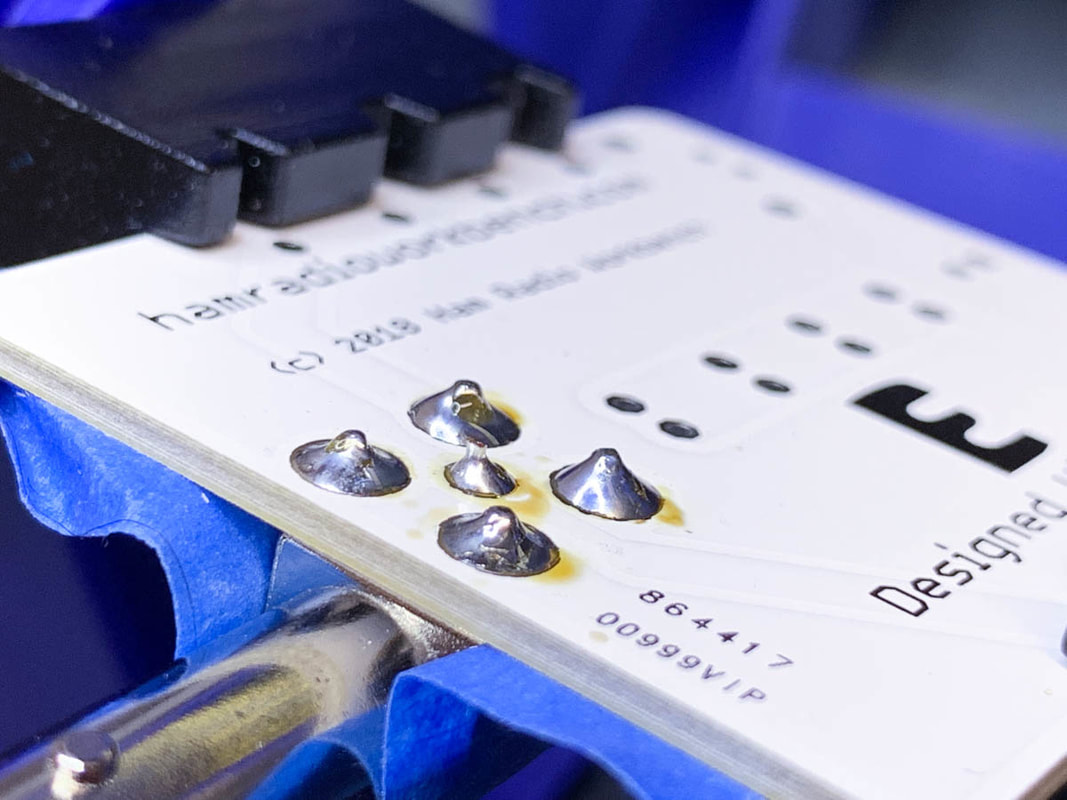

Caution! - This unit will get hot even with brief RF exposure (15 watts for 60 second resulted in 200F temperatures). Use only in short bursts and with good ventilation and maybe a small fan to dissipate heat! |

Parts / Supplies |

|

Buy Now |

Documentation |

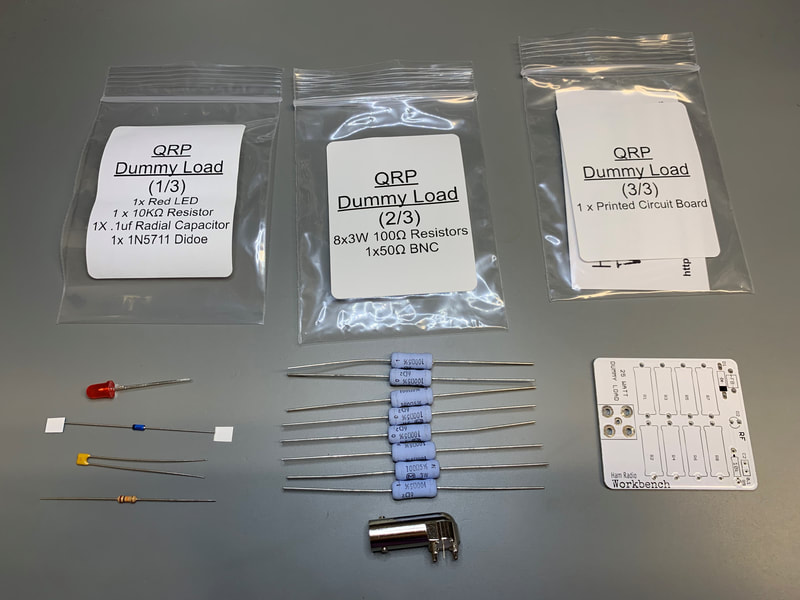

To assemble this project, you will need the following tools and supplies:

To make the project even easier, the following items are helpful

General Guidelines

|